The Impact and Legacy of Futurism in Art and Design

In the tumultuous early 20th century, marked by a whirlwind of new inventions and a shift from agrarian to urban...

Before industrialization, items were crafted in small quantities, each piece being more or less handcrafted with subtle differences, carrying the emotions and fingerprints of its creator from the moment of creation. The advent of the industrial revolution, marked by the invention of steam-powered engines and mass production, brought about significant changes. Now, let’s explore the events that led to these transformations and their impact on the history of design.

Before industrialization

Life in the 18th century differed significantly from the present day. The majority, nine out of ten people, lived in rural areas. Society was characterized by a large impoverished lower class, a small affluent upper class, and a limited middle class. The absence of modern conveniences such as electric lights, movies, telephones, recorded music, cars, trains, and artificial engine noise defined daily life. People relied on manual labor to create the items they needed, and food was primarily produced on small farms. The concept of a daily commute to work was virtually nonexistent, and even clocks were deemed unnecessary as people synchronized their lives with the natural rhythm of the rising and setting sun.

In the 18th century, early entrepreneurs sought to increase productivity while reducing costs. They employed methods such as the ‘division of labor‘ or ‘deskilling of the workers.’ The concept involved breaking down the production process into smaller tasks, allowing unskilled workers to specialize in a single step and become proficient in it. This approach aimed to decrease the time required for crafting a single piece by a skilled craftsman. Concurrently, innovations in casting products, notably pioneered by Abraham Darby, facilitated cost reduction through the reuse of casts for repetitive production.

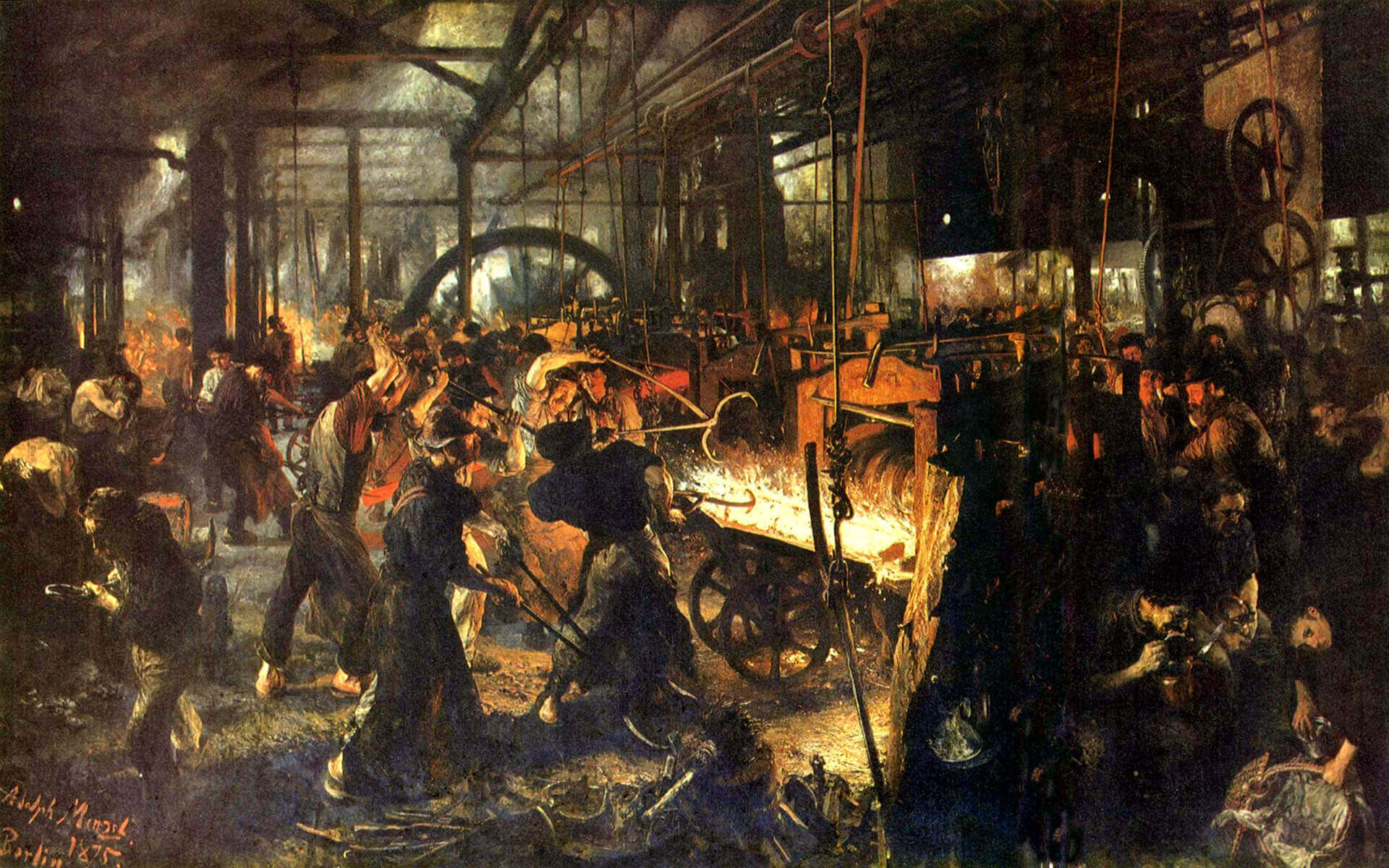

In the late 1700s and early 1800s, factories, large buildings where a small number of workers operated expensive and intricate machines, began to emerge in Europe and North America. These factories revolutionized manufacturing, producing goods for the mass market. This marked a turning point for human society, as a significant number of people now had to leave their homes daily to work and earn a living.

New production methods, coupled with technological innovations, accelerated and diversified industrialization across various disciplines. Urbanization surged as more individuals left rural areas for cities, intensifying competition for employment. However, the industrial landscape presented challenges. Machines were often loud and hazardous, working hours were long, wages were low, and tasks were monotonous. Factory air was filled with fibers that posed risks to workers’ lungs. Despite these challenging working conditions, there was a consistent supply of individuals willing to accept employment. On the positive side, mass production drastically increased accessibility and affordability of basic necessities, such as clothes and household items, which were once limited to a few.

New housing for workers had to be constructed near the factories, leading to rapid urban growth as the number of people residing in rural areas significantly declined. Additionally, due to the necessity for factories to meet specific production deadlines, workers were required to adhere to strict schedules, marking the first time in history when the lives of many people became regulated by the ticking of clocks and the ringing of factory bells.

Textile manufacturing was the initial major industry to undergo transformation during industrialization, significantly impacting the impoverished rural class. In addition to their unpredictable income from farming, the primary source of livelihood for this class was domestic or cottage industries involving the production of threads and cloth. With the onset of the industrial revolution, these traditional home-based textile workers became the first to be replaced by machines.

In the 1760s, two revolutionary machines, the Spinning Jenny and the Water Frame, transformed the textile industry by significantly accelerating the process of thread production for weaving. Powered by hydraulics, these machines marked a significant leap in efficiency. Subsequently, the Spinning Mule, developed later and connected to watermills, allowed a single worker to accomplish the work of 3000 hand spinners. These highly efficient machines produced high-quality, low-cost clothing threads, leading to the collapse of the traditional home cottage industry. Additional developments, such as the Flying Shuttle, which enabled the weaving of numerous threads into textiles, further contributed to the decline of the cottage weaving industry.

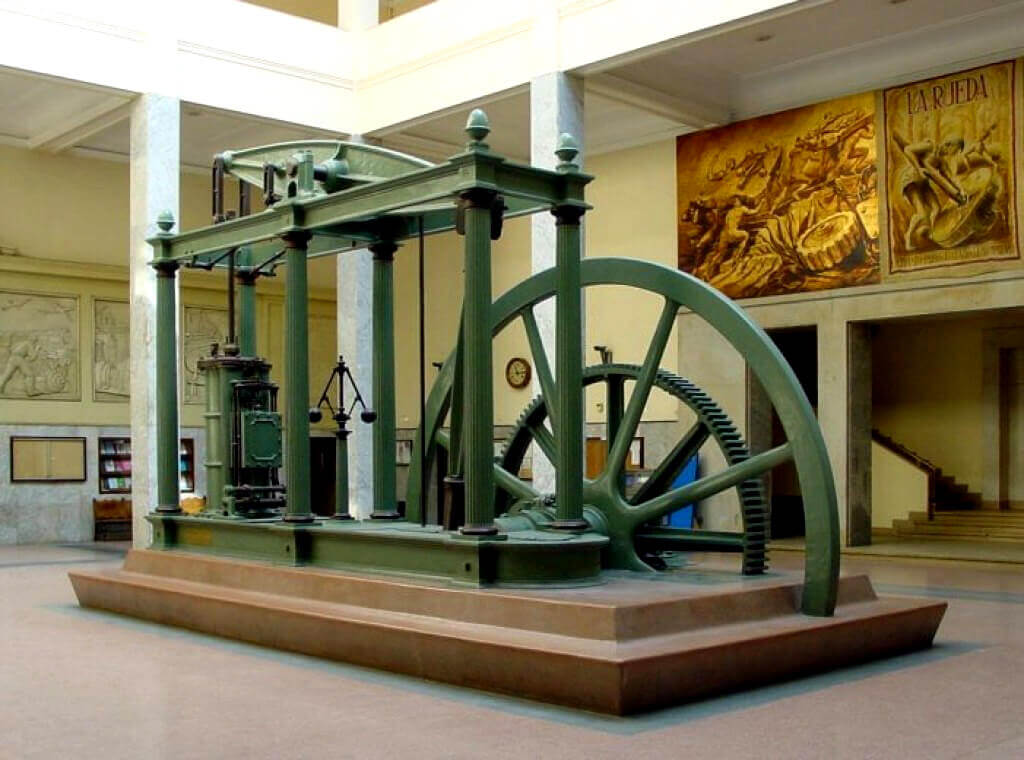

The shift from water to steam power played a pivotal role in accelerating the Industrial Revolution, bringing about profound changes in manufacturing, transportation, and farming. The first steam-powered engine with pistons was invented by Thomas Newcomen around 1712. Initially designed to pump water out of coal mines, this innovation facilitated deeper mining, allowing for increased coal extraction to power more steam engines.

Later, James Watt improved Newcomen’s engine, eventually modifying it to provide rotary motion suitable for driving factory machinery. This innovation allowed factories to be located away from rivers, traditionally powered by watermills, and further accelerated the Industrial Revolution.

Amidst these transformations, characterized by the deskilling of craftsmen, mass production, the expansion of factories, and the growth of cities, a reaction emerged in the late 19th century known as the Arts and Crafts movement. In the next post, we will explore the reasons behind this movement, which originated in Britain, and examine its enduring impact.

In the tumultuous early 20th century, marked by a whirlwind of new inventions and a shift from agrarian to urban...

As the twentieth century unfolded, emerging artists sought inspiration beyond the intricate designs of the Victorian era, Art Nouveau, and...

The Art Nouveau movement, which flourished in the late 19th and early 20th centuries, was characterized by its ornamental and...

As the 19th century unfolded, the city of Paris became a hotbed of optimism and creativity, fueled by a confluence...

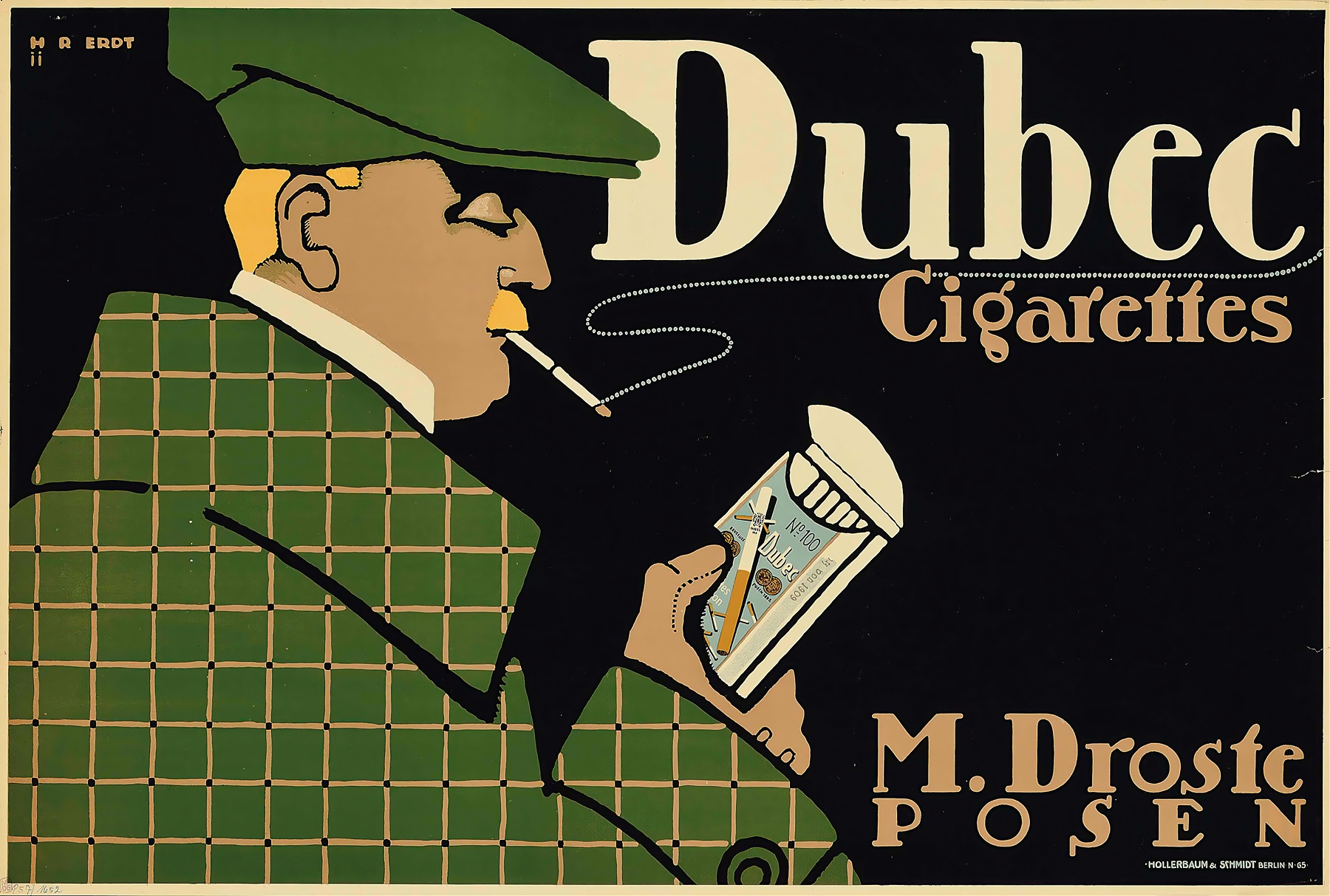

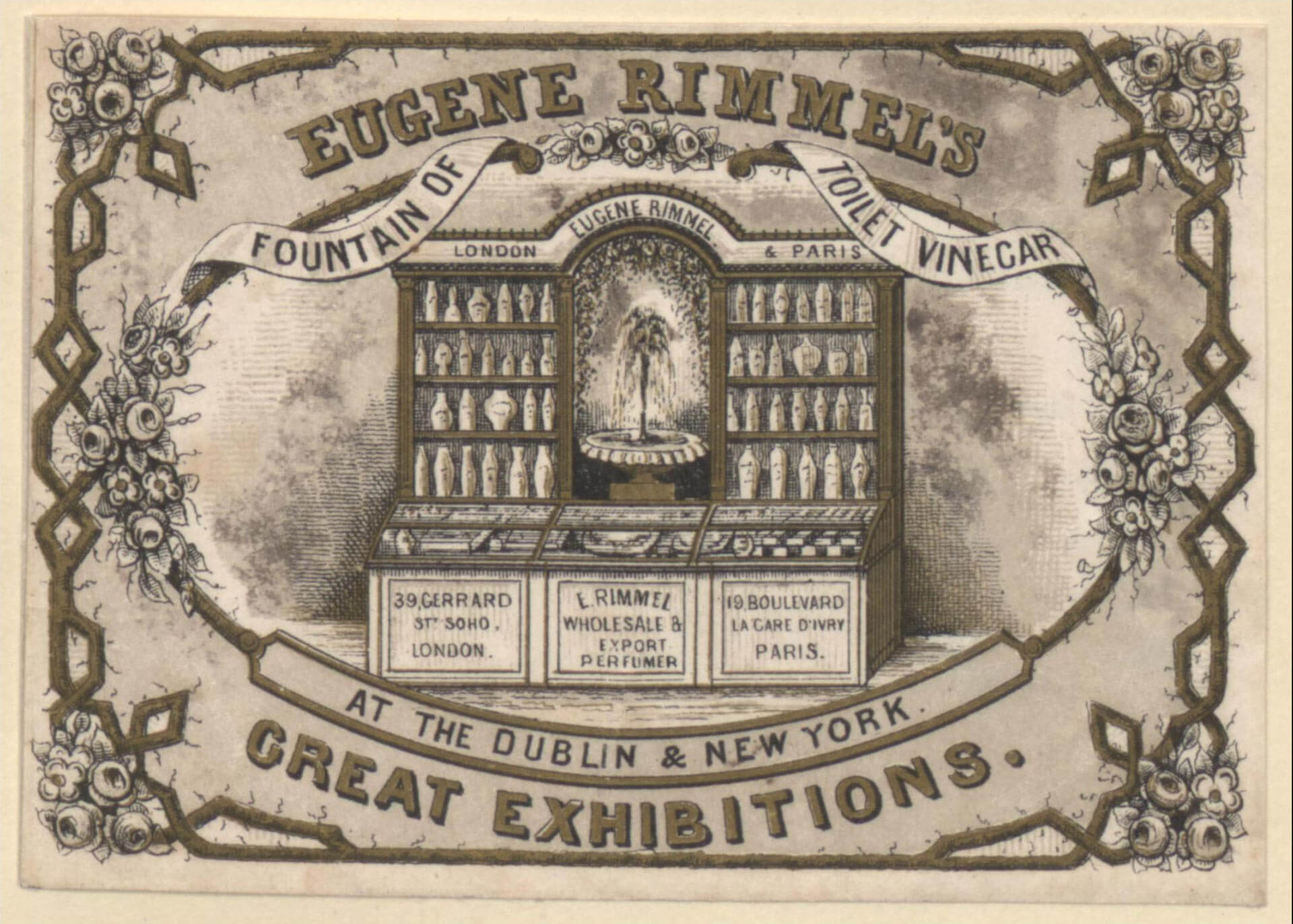

In the mid to late 19th century, the technological change was a big driving force, just like today. The new...

While these developments were happening, the deskilling of the craftsman and manufacturing of mass-produced items, expansion of factories and even...

Before industrialization, things were made in small numbers, carrying the emotions and fingerprints of its creator as a result of...

In 1400s AD, after several years of focused experiments, Johannes Gutenberg made the system scalable and led the way for...

The history of graphic design begins with the cave paintings. The prehistoric humans were marking their daily lives or the...

Starting from a simple stone ax, throughout the history we created a man-made environment, to survive and control the world...